Dynamic viscosity

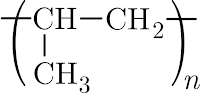

Material Dynamic viscosity, Pa·s Air (temp. 20 0 C) 10 -5 Water (temp. 20 0 C) 10 -3 Mercury (temp. 20 0 C) 1,5·10 -3 Aluminum (temp. 700 0 C) 1,1·10 -3 Zinc (temp. 700 0 C) 1,7·10 -3 Iron (temp. 1400 0 C) 6·10 -3 Blood (temp. 37 0 C) 10 -2 Oil 10 -2 -10 0 Honey 10 1 Melted polymers 10 2 -10 4 Cake 10 3 -10 5 Cheese 10 7 -10 8 asphalt 10 8 Melted glass (temp. 500 0 C) 10 12 Glass 10 40